Precision and Versatility in Cylindrical Grinding #

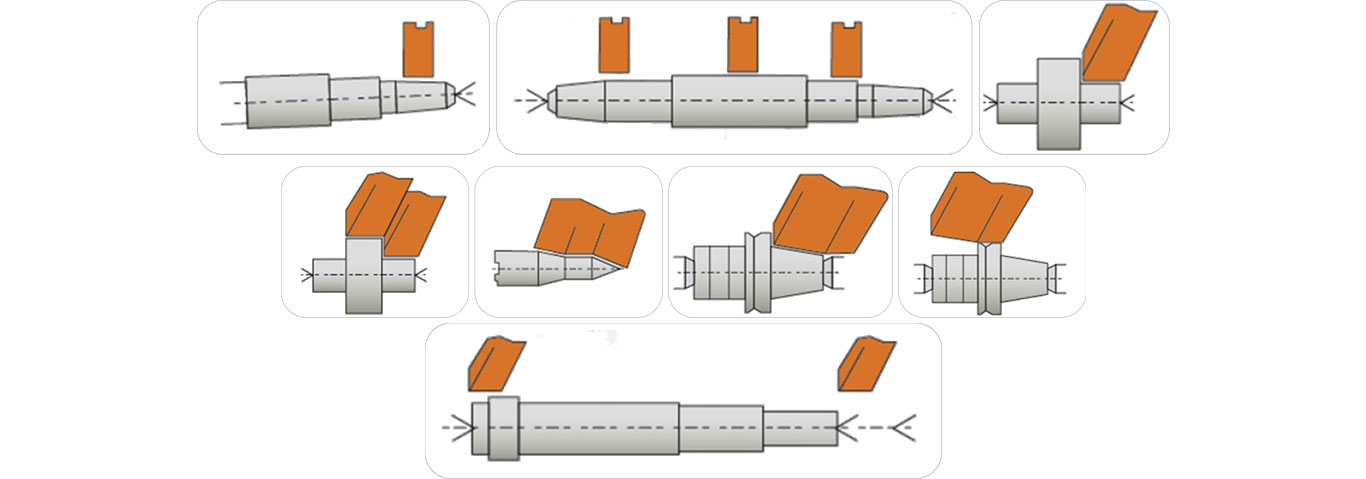

The GO-354 CNC Cylindrical Grinder is engineered to provide both plunge and angular grinding, supporting a wide range of complex and varied grinding tasks. Its design enables multiple grinding operations within a single setup, reducing machining time and increasing productivity—especially for small and precision components. For larger workpieces, consider the GO-356 CNC cylindrical grinder.

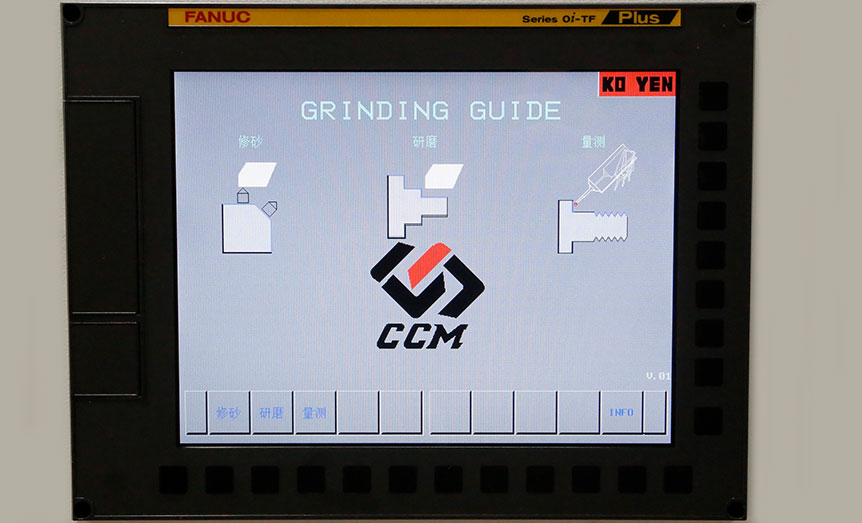

Customizable Operation Panel #

The operation panel is designed for intuitive use, accommodating user preferences and ensuring efficient machine control.

Ergonomic Pictogram-Based Controls #

The GO-354 utilizes original pictogramming based on the FANUC system. All controls are clearly and ergonomically arranged, with a manual control unit that simplifies setup close to the grinding process. Built-in security settings and error warnings help prevent input errors, allowing even new operators to complete setup and manufacturing procedures with confidence.

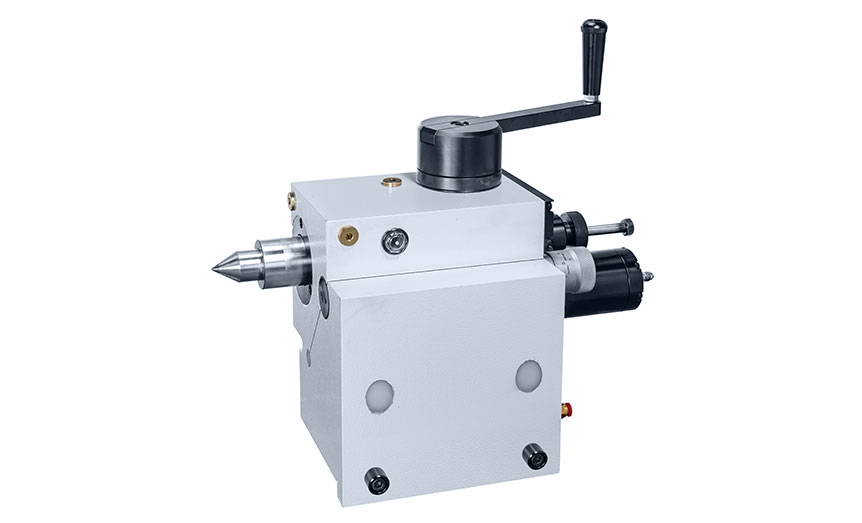

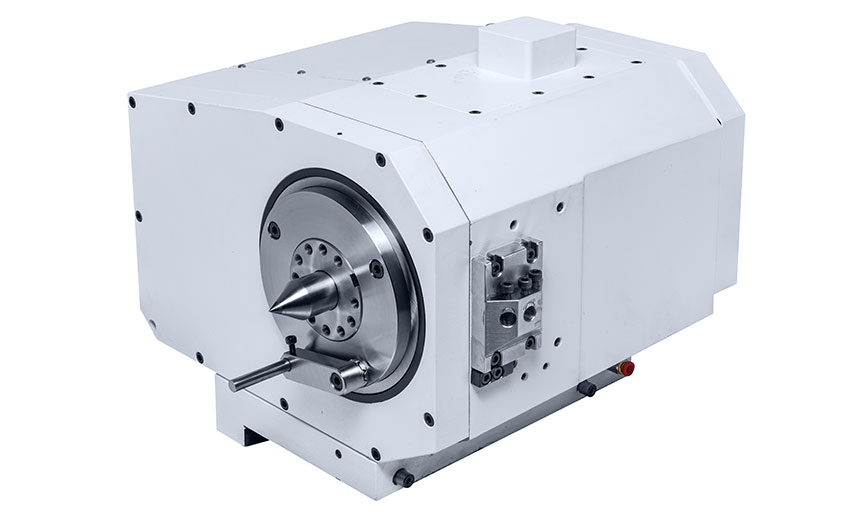

Precision Tailstock #

The tailstock features a generously dimensioned barrel designed for Morse 4 taper centers. Center pressure is finely adjustable for high-precision grinding, with taper corrections possible below 1 µm. A pneumatic lifting process streamlines movement during setup and resetting.

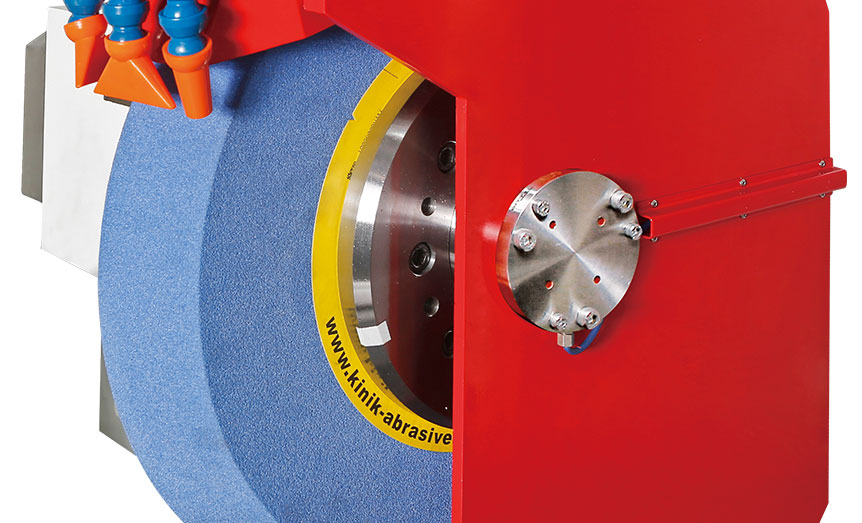

Integrated Acoustics Monitoring System #

The built-in acoustics monitoring system reduces wheel dressing cycle time, improves efficiency and stability, prevents wheel crashes, and increases spindle and wheel service life. By monitoring grinding quality in real-time, machining accuracy is assured.

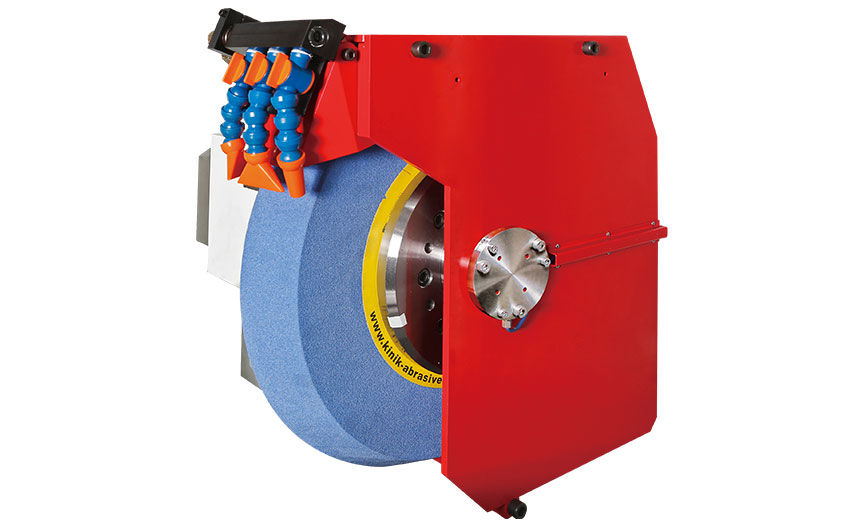

High-Performance Wheelhead #

The wheelhead features a built-in spindle for high torque and stability. Customers can choose between vertical or 30° configurations. The wheel supports linear speeds up to 60 m/s (wheel dimension: 510 x 60 x 203 mm).

Optional Workhead C-axis #

With specialized software, the optional C-axis enables non-circular and thread grinding capabilities.

Fine Adjustment for Taper Corrections #

Fine adjustment allows for taper corrections within a 1 µm range (total range ± 20 µm).

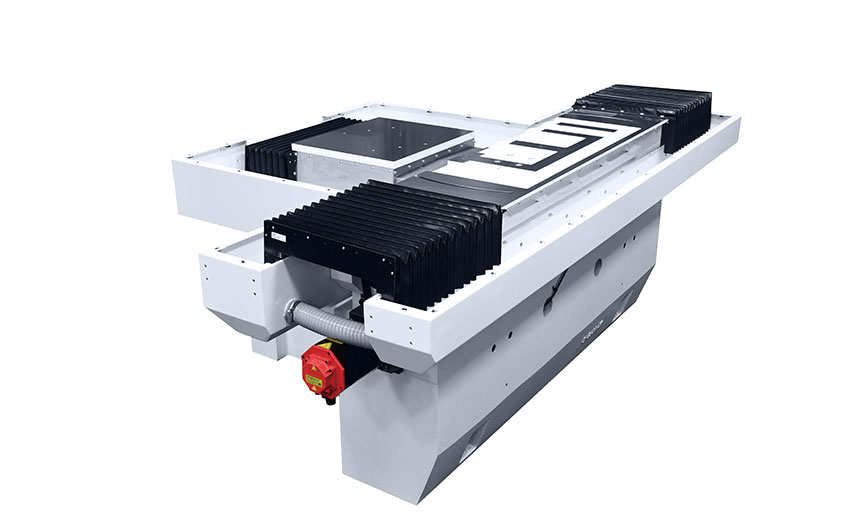

Robust Machine Base #

A high-rigidity structure ensures optimal grinding stability.

Key Features #

- Supports both angular and plunge type grinding

- Maximum grinding speed up to 60 m/s

- High-rigidity structure for stable grinding

- Achieves circularity of 0.8 µm

- X and Z axes feature V-type and planar hard tracks

- Equipped with FANUC Oi-TF Plus controller

- Integrated acoustics monitoring system

- Multiple automatic loading/unloading options (optional)

- Tailstock with air buoyance for quick adjustments

- Optional online measurement system

- Optional thread and non-circular grinding

- Optional wheel balancers for monitoring wheel condition

Technical Specifications #

| Type | GO-354 | GO-356 |

|---|---|---|

| Distance Between Centers | 400 mm | 650 mm |

| Workpiece Length | 400 mm | 650 mm |

| Center Height | 175 mm | 175 mm |

| Max. Workpiece Weight | 80 kg | 80 kg |

| X Axis Max. Travel | 250 mm | 250 mm |

| X Axis Speed | 0.001-10000 mm/min | 0.001-10000 mm/min |

| Z Axis Max. Travel | 620 mm | 880 mm |

| Z Axis Speed | 0.001-10000 mm/min | 0.001-10000 mm/min |

| Wheelhead Max. Spindle Power | 7.5/12 kW | 7.5/12 kW |

| Wheel Dimension | 510×60/80×203 mm | 510×60/80×203 mm |

| Wheel Linear Velocity | 50-60 m/s | 50-60 m/s |

| Workhead Revolve Speed Range | 1-1000 RPM | 1-1000 RPM |

| Workhead Max. Spindle Power | 1.2 kW (FANUC) | 1.2 kW (FANUC) |

| Speed Reduction Ratio | 1:3 | 1:3 |

| Grinding Circularity | < 0.8 µm | < 0.8 µm |

| Center Taper | MT4 | MT4 (STD), MT5 (option) |

| Tailstock Center Taper | MT3 (STD), MT4 (option) | MT4 |

| Max. Sleeve Travel | 35 mm (1.37") | 35 mm (1.37") |

| Sleeve Diameter | 50 mm | 50 mm |

| Taper Fine Tuning Travel | ±20 µm | ±20 µm |

| Control System | FANUC 0i-TF Plus | FANUC 0i-TF Plus |

Application Industries #

- Part of Machine Spindle

- Vehicle Transmitting Gear

- Mold Manufacturing

- Medical Instrument

- Aerospace Industry

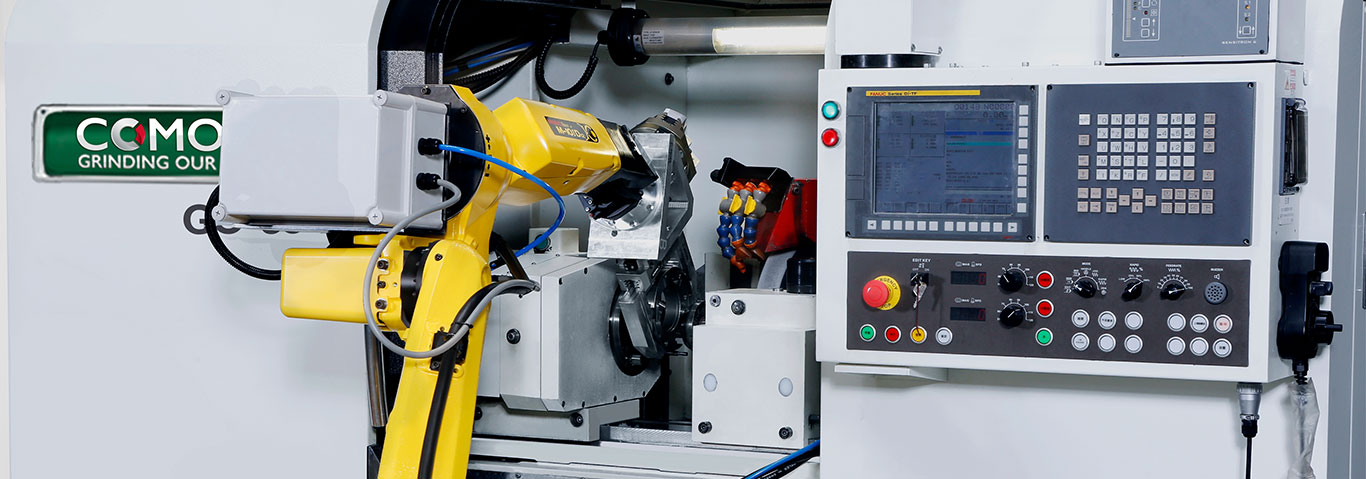

Smart Factory Integration #

The integration of robotic arms marks a significant step towards a smart factory environment. This advancement enhances manufacturing flexibility and safety, enabling immediate collaboration and streamlined processes.

Multifaceted Processing in a Single Setup #

Specialized controller software enables the grinding of complex workpieces and multifaceted processing in a single operation. This approach ensures high efficiency and precision while reducing manufacturing costs.

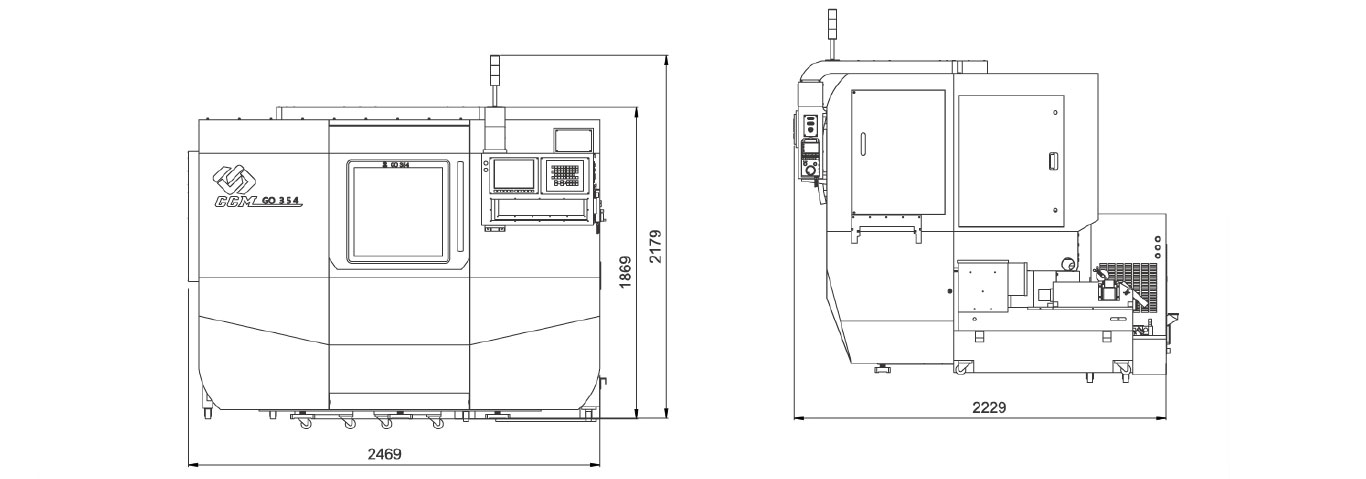

Machine Dimensions #

If you are interested in learning more about our products or have specific requirements, please contact us.