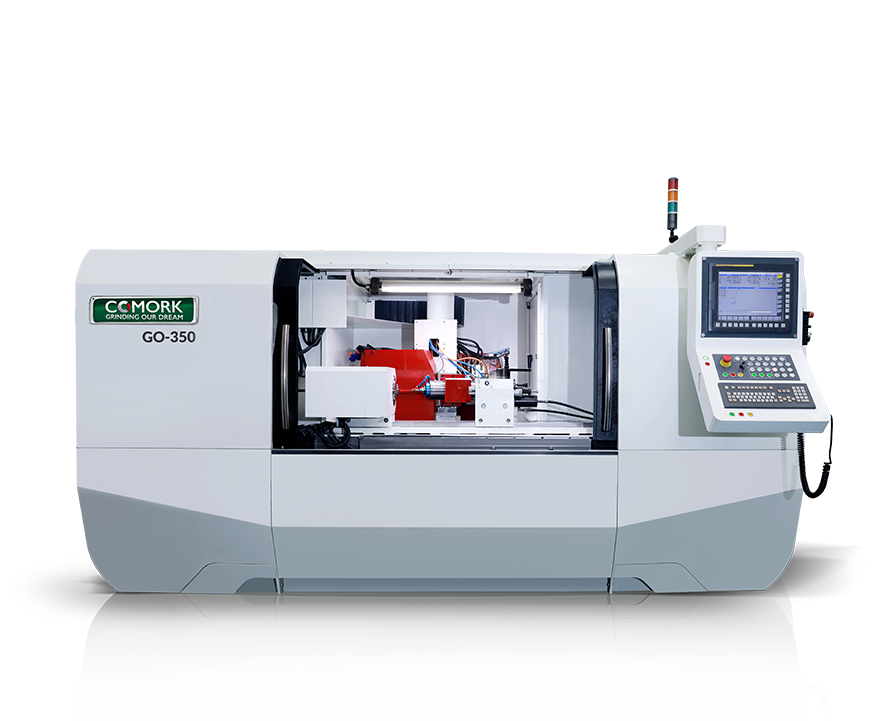

Advanced CNC ID/OD Grinding for Versatile Applications #

The GO-350 CNC Hybrid ID & OD Grinder is engineered to deliver high-precision grinding for both inner and outer diameters. Leveraging a robust CNC system, this machine ensures automated, accurate, and efficient grinding operations. Its versatility makes it an excellent fit for industries such as automotive, aerospace, manufacturing, medical, and tool and die sectors.

Key Features #

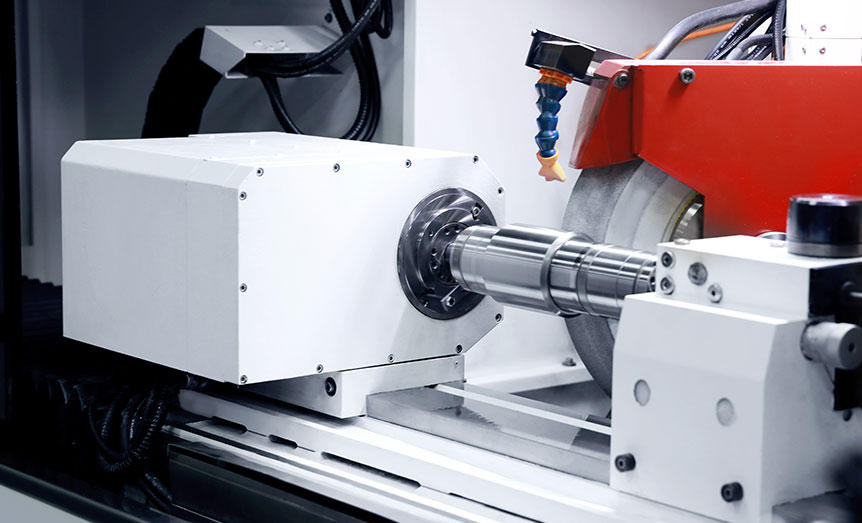

- Turret Wheelhead: Equipped with G1 (OD), G2 (OD), and G3 (ID) to handle complex workpieces. This configuration streamlines processing programs and enhances the machine’s utility.

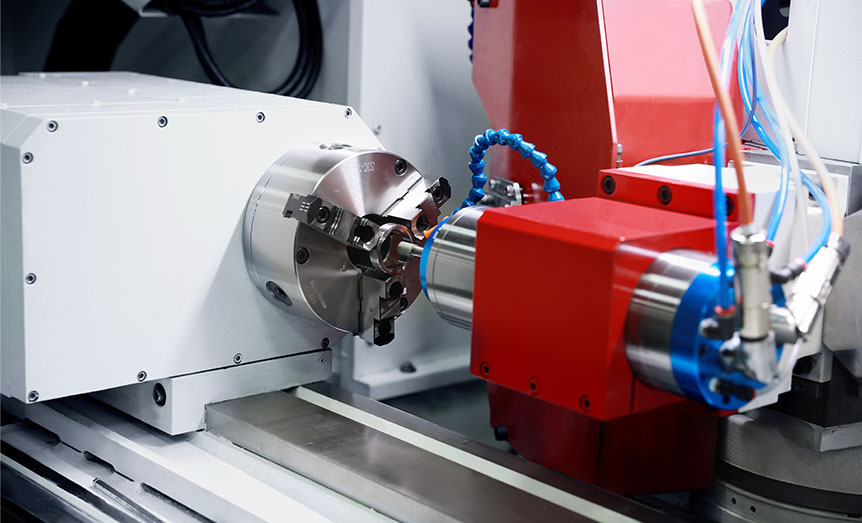

- Workhead: Driven by a FANUC servo motor, offering high torque and stability for demanding grinding tasks.

- Power Transmission: Utilizes a precision ballscrew with servo motor drive and HEIDENHAIN linear encoder, ensuring superior axial motion positioning accuracy.

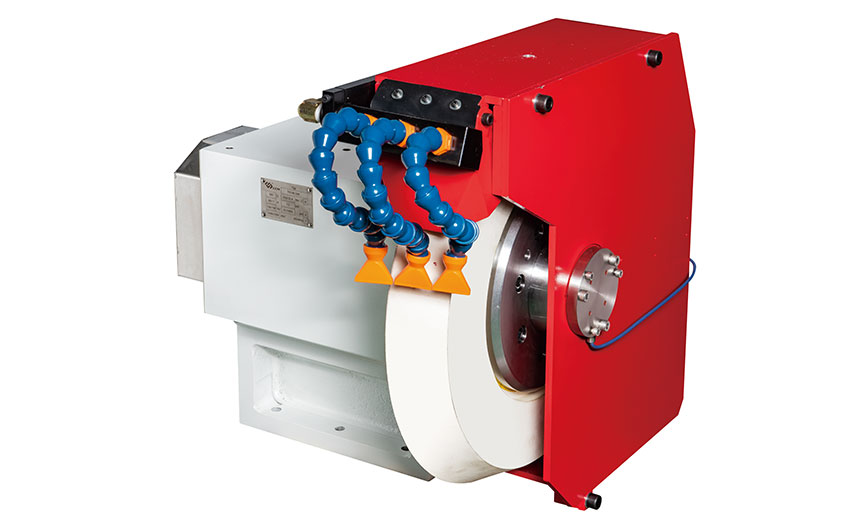

- Grinding Wheel: Features a built-in spindle with high rigidity and torque. The wheel head can be customized to specific requirements and operates reliably within a temperature range of -10°C to 240°C.

Enhanced Operator Experience #

- Customization Operate Panel: Designed for intuitive operation, the panel accommodates user preferences for optimal control.

- Fanuc 15” Touchscreens: Delivers a modern, responsive interface for streamlined machine management.

Specialized Components #

- ID Grinding Equipment: Supports precise internal diameter grinding.

- Tailstock: Features a generously dimensioned barrel for Morse 4 taper centers, with finely adjustable center pressure for high-precision workpieces. Taper corrections below 1 μm are possible, and a pneumatic lifting process aids setup and resetting.

- Wheelhead: Utilizes a built-in spindle for high torque and stability. Options for vertical or 30° orientation are available. Wheel linear speed can reach up to 60 m/s (wheel dimension: 510 x 60 x 203 mm).

- Workhead C-axis (Optional): With dedicated software, the C-axis enables non-circular and thread grinding for advanced applications.

Technical Specifications #

| Type | Unit | Value |

|---|---|---|

| Distance between Centers | mm | 1000 / 650 / 400 |

| Grinding Length | mm | 1000 / 650 / 400 |

| Center Height | mm | 175 |

| Max. Workpiece Weight | kg | 150 / 80 |

| Cross Slide (X-axis) Max. Travel | mm | 275 / 250 |

| Cross Slide (X-axis) Speed | mm/min | 0.001~10000 |

| Longitudinal Slide (Z-axis) Max. Travel | mm | 1150 / 880 / 620 |

| Longitudinal Slide (Z-axis) Speed | mm/min | 0.001~10000 |

| Wheelhead Assembly | Fixed / Turret | |

| Wheelhead Rotation Range | 0° / 15° / 30° or -10°~240° | |

| Direct Drive Power | kW | Up to 11 |

| Grinding Wheel Spec | mm | 500 x 60 x 203 |

| Grinding Wheel Linear Speed | m/s | 60 |

| Internal Grinding Spindle Hole Diameter | mm | 120 |

| Driving Power | kW | 15 |

| Spindle Rotation Speed | rpm | 8,000~30,000 |

| Workhead Speed Range | rpm | 1~1000 |

| Workhead Drive Power (Fanuc) | kW | 1.8 / 1.2 |

| Grinding Roundness Accuracy | mm | < 0.0008 |

| Assembly Taper | MT4 / MT5 | |

| Tailstock Matching Taper Hole | MT3 / MT4 | |

| Tailstock Sleeve Travel | mm | 35 (1.37") |

| Tailstock Sleeve Diameter | mm | 50 |

| Grinding Taper Precision Fine Adjustment | μm | ±20 |

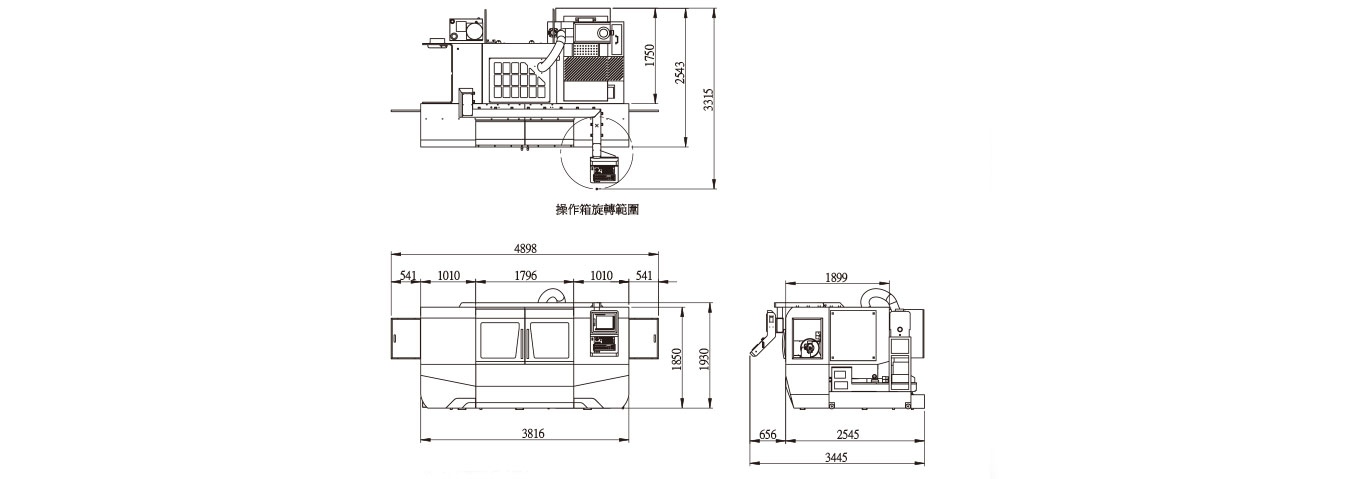

Machine Dimensions #

Drawing unit: mm

For further details or to discuss your specific requirements, please contact us.