Advanced CNC ID & OD Grinding Capabilities for Versatile Production #

The GJ-412 CNC external internal grinding machine is engineered to accommodate a wide range of workpiece sizes and shapes, making it a robust solution for modern manufacturing environments. With a maximum workpiece diameter of Ø 450 mm and a length of up to 1,000 mm, this machine is well-suited for both small and large-scale grinding operations. The workhead offers variable speeds from 0 to 1,000 rpm, ensuring adaptable and precise processing for diverse applications.

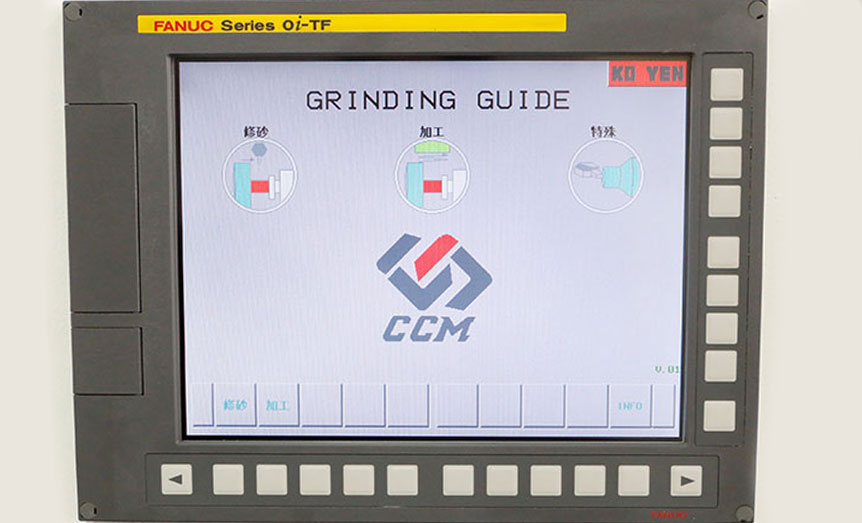

Intuitive Control and Enhanced Safety #

The machine features an original pictogram interface based on the FANUC system, with all controls clearly and ergonomically arranged. The manual control unit is positioned close to the grinding process, simplifying setup procedures. Built-in security settings and error warnings help prevent operator errors, making it accessible even for less experienced users.

Precision Adjustment for Superior Results #

Fine adjustment capabilities allow for taper corrections in the 1µm range, with a total adjustment range of ±20 µm. This ensures that even the most demanding precision requirements can be met with confidence.

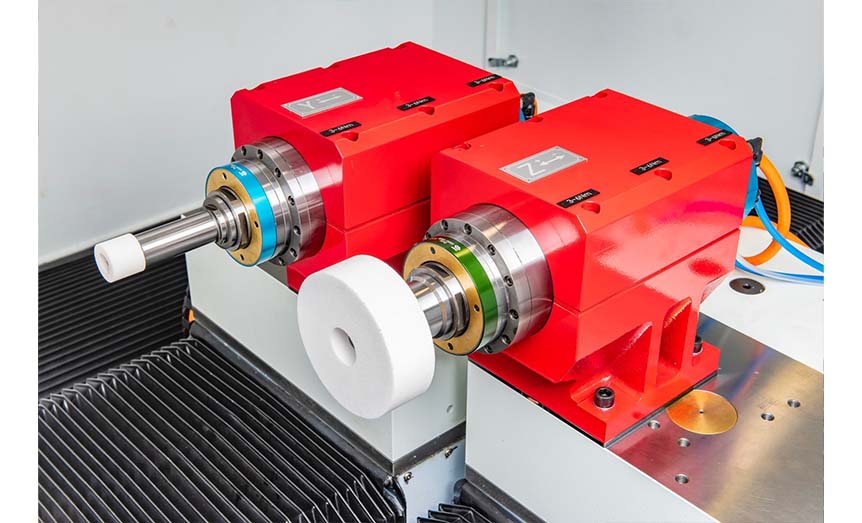

Dual Grinding Spindle for Comprehensive Processing #

The dual grinding spindle design enables the GJ-412 to perform internal diameter (ID), external diameter (OD), end face, and bevel grinding in a single process. This significantly improves efficiency and reduces handling time. The grinding spindle options include:

- Belt driven: 8,000~50,000 rpm

- Built-in motor: 8,000~120,000 rpm

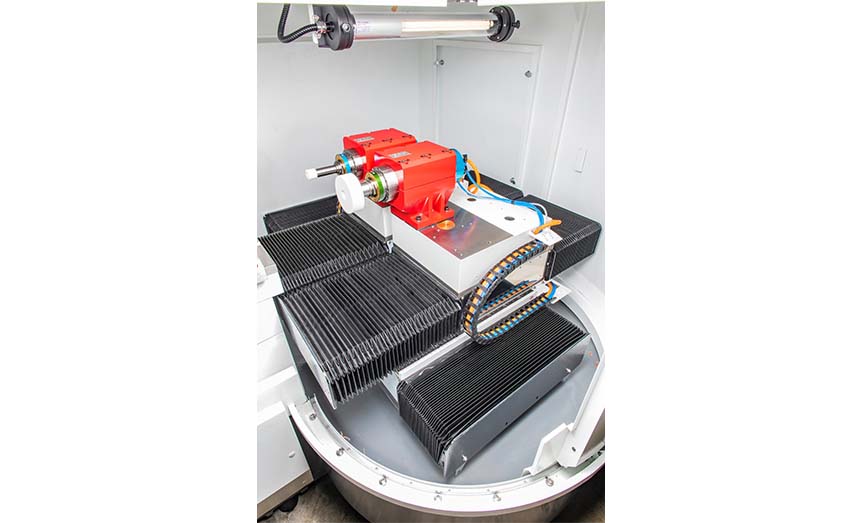

Rigid Machine Base for Stability #

A high-rigidity machine base ensures optimal grinding stability, supporting consistent and accurate results throughout long production runs.

Key Features at a Glance #

- Manually adjustable spindle plane (B Axis) from 0˚ to 15˚ for enhanced flexibility in complex grinding tasks.

- Internal diameter processing range: 0 to 300 mm; external diameter grinding up to ¢360 mm; maximum grinding length: ¢300 mm.

- Supports workpieces up to 120 kg.

- Processes up to eight faces in a single cycle, streamlining production.

- Standard embedded spindle with a wide speed range and high cutting ratios for maximum efficiency.

- Capable of internal, external, end face, and inclined surface grinding in one step.

- X, Y, Z axes equipped with high-precision linear guides.

- Dual grinding wheel spindle structure for high-efficiency ID/OD grinding.

- B-axis with ring optical encoder for precise rotational positioning.

- Multi-surface grinding with single clamping.

- Equipped with FANUC 0i-TF CNC controller.

- Optional non-circular grinding function.

- Semi-circular base design reduces space usage; thick, stable, and rigid body structure for optimal stability.

- Fully enclosed guard for safety.

Technical Specifications #

| CATEGORY | GJ-412-500 / GJ-412-1000 |

|---|---|

| Maximum Workpiece Diameter | Ø 450 mm |

| Workhead Revolve Speed | 0 ~ 1,000 rpm |

| Spindle Plane Manual Angle Adjust (B Axis) | 0˚ ~ 15˚ |

| ID Processing Scope | 0 ~ 300 mm |

| Maximum Grinding Outer Diameter Range | ¢360 mm |

| Maximum Grinding Length | ¢300 mm |

| Maximum Workpiece Length | 1,000 mm |

| Maximum Number of Faces Processed in One Cycle | 8 |

| Load Capacity of Workpiece | 120 KG |

| Maximum Travel of X-axis | 550 mm |

| Maximum Travel of Y-axis | 375 mm |

| Maximum Travel of Z-axis | 375 mm |

| X-axis Travel Speed | 0 ~ 10,000 mm/min |

| Y-axis Travel Speed | 0 ~ 10,000 mm/min |

| Z-axis Travel Speed | 0 ~ 10,000 mm/min |

| Minimum Travel Unit of X-axis | 0.0001 mm |

| Minimum Travel Unit of Y-axis | 0.0001 mm |

| Minimum Travel Unit of Z-axis | 0.0001 mm |

| Spindle Motor for X-axis Clamp | Servo Motor 1.2KW |

| Power Demand | 20 kW |

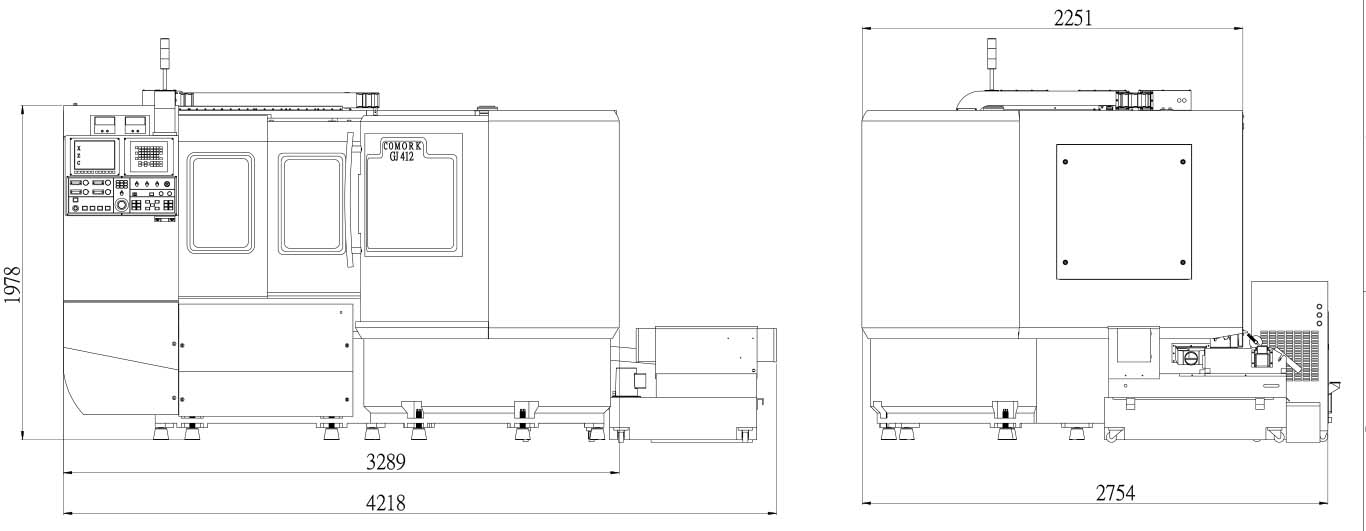

| Mechanical Dimensions | 275432891978 mm |

| Machine Net Weight | 9,500 Kg |

Machine Measurement Diagram #

For further details or to discuss your specific requirements, please contact us.