Advanced CNC Grinding for Multifaceted Precision Work #

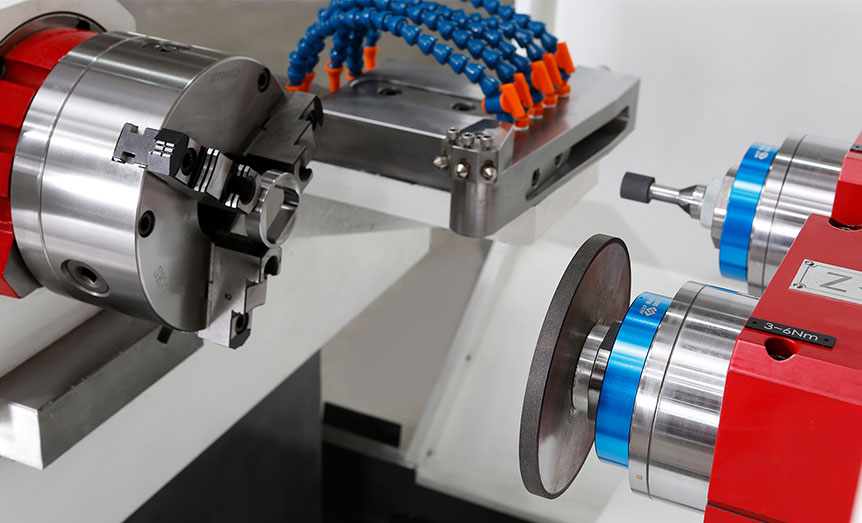

The GJ-400 CNC Hybrid ID & OD Cylindrical Grinding Machine is engineered to streamline complex grinding tasks by combining both internal and external cylindrical grinding capabilities in a single, efficient process. This hybrid approach enables users to perform ID and OD grinding in one clamping, significantly reducing equipment and labor costs while boosting productivity and versatility.

Key Features #

-

Automatic Sensing Function: Monitors spindle motor current to detect contact with the workpiece, eliminating empty strokes and minimizing human error for improved efficiency.

-

Customizable Operation Panel: Ergonomically designed for intuitive user interaction, tailored to operator preferences.

-

Handwheel Control System: Allows switching to handwheel mode during program execution for precise setup adjustments.

-

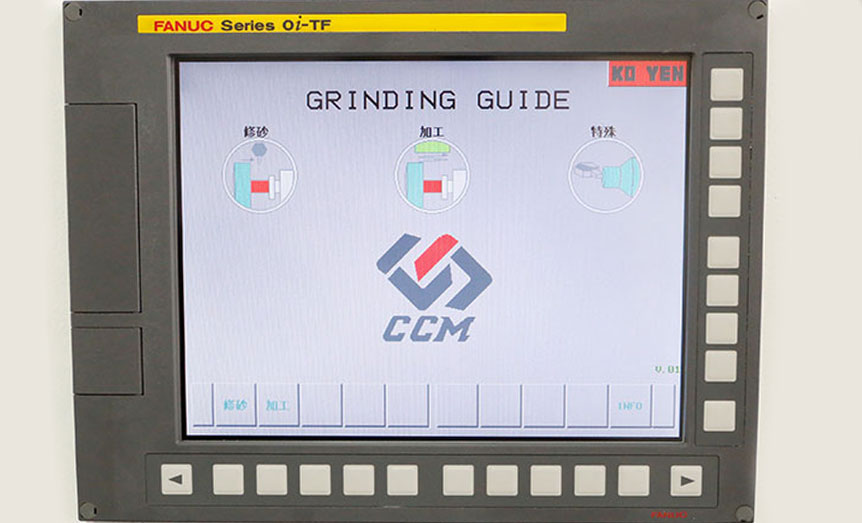

FANUC-Based Pictogram Interface: Clear, ergonomic controls with built-in security and error warnings, making setup accessible even for new operators.

-

Dual Grinding Spindle: Capable of simultaneous inner/outer diameter and end face grinding in a single process. Available spindle types include:

- Belt-driven: 8,000–50,000 rpm

- Built-in motor: 8,000–120,000 rpm

-

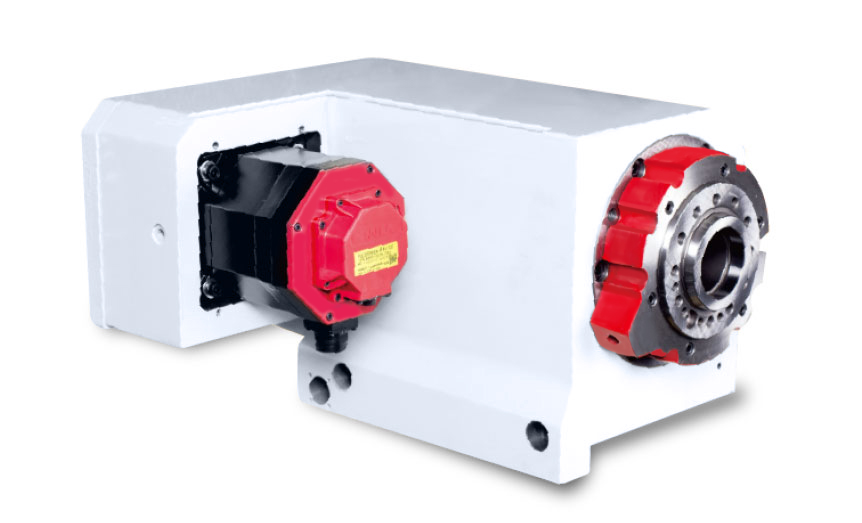

Optional Workhead C-axis: With specialized software, enables non-circular and thread grinding.

-

66mm Through Hole Workhead Spindle (Option): Supports longer, heavier workpieces with enhanced rigidity.

-

Fine Adjustment Mechanism: Allows taper corrections within a 1μm range (total range ±20μm).

-

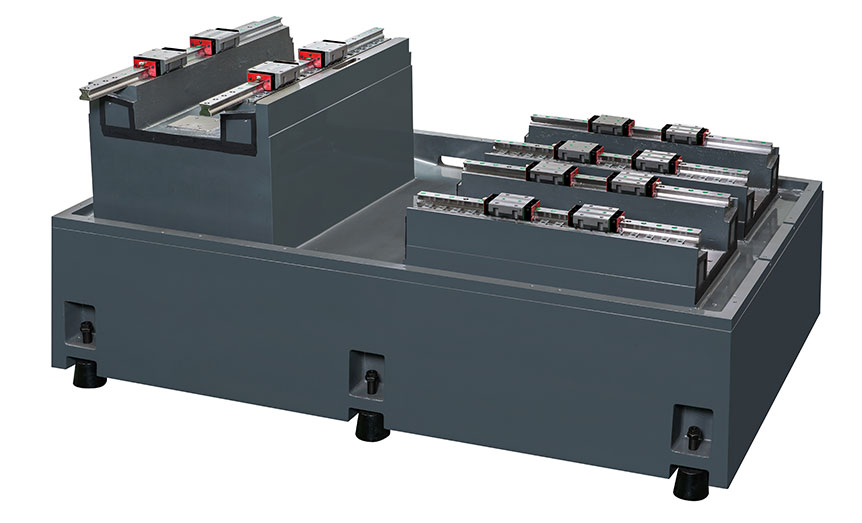

High-Rigidity Machine Base: Ensures optimal grinding stability.

-

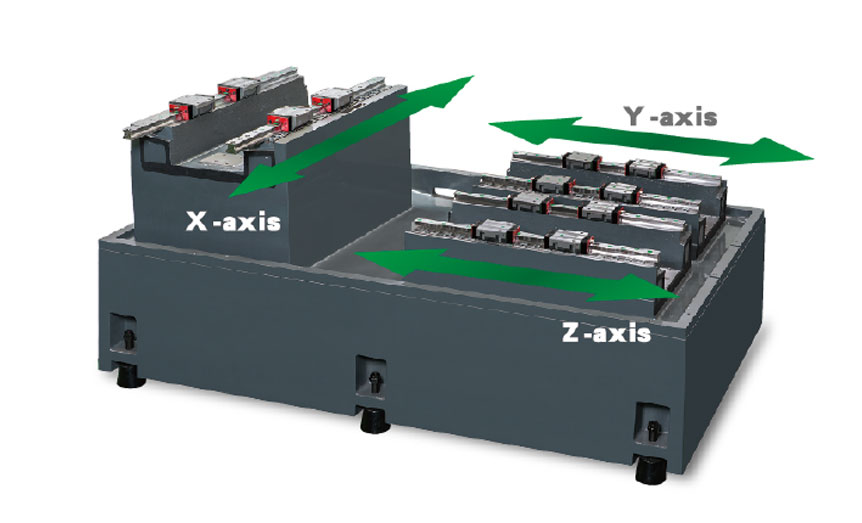

Precision Linear Guides: X, Y, and Z axes equipped with high-precision linear guides for consistent accuracy.

Technical Specifications #

| Type | GJ-400A | GJ-400B |

|---|---|---|

| Max. Workpiece Diameter | Ø 400 mm | Ø 400 mm |

| Workhead Revolve Speed | 0 ~ 1,000 rpm | 0 ~ 1,000 rpm |

| Spindle Plane Manual Angle Adjust | +15˚ & -2˚ | +15˚ & -2˚ |

| Max Travel: X axis | 360 mm | 360 mm |

| Max Travel: Y / Z axis | 340 + 240 mm | 340 + 240 mm |

| ID Processing Scope | Ø 0 ~ 310 mm | Ø 0 ~ 310 mm |

| OD Processing Scope | 380 mm x 100 mm | 380 mm x 100 mm |

| Length Processing Scope (ID) | 250 mm | 250 mm |

| Max. Workpiece Weight | 56 kg | 56 kg |

| X / Y / Z Axis Travel Speed | 0 ~ 10,000 mm/min | 0 ~ 10,000 mm/min |

| Axis Travel Unit | 0.001 mm | 0.001 mm |

| Spindle Motor Type | 3HP 2kw 2P | AIF8 / 3,000 1.6 kw |

| Wheel head A-5 Spindle Rotation Speed | 8,000 ~ 50,000 rpm | 8,000 ~ 50,000 rpm |

| Power Demand | 15 kw | 15 kw |

| Machine Net Weight | 4,500 kg | 4,500 kg |

Multifaceted Processing in a Single Setup #

With specialized controller software, the GJ-400 is capable of handling complex workpieces and multifaceted processing in one operation. This approach ensures high efficiency and precision, while reducing manufacturing costs.

Industry Applications #

The GJ-400 is suitable for a wide range of industries, including:

- Machine Spindle Components

- Vehicle Transmission Gears

- Mold Manufacturing

- Medical Instruments

- Aerospace Industry

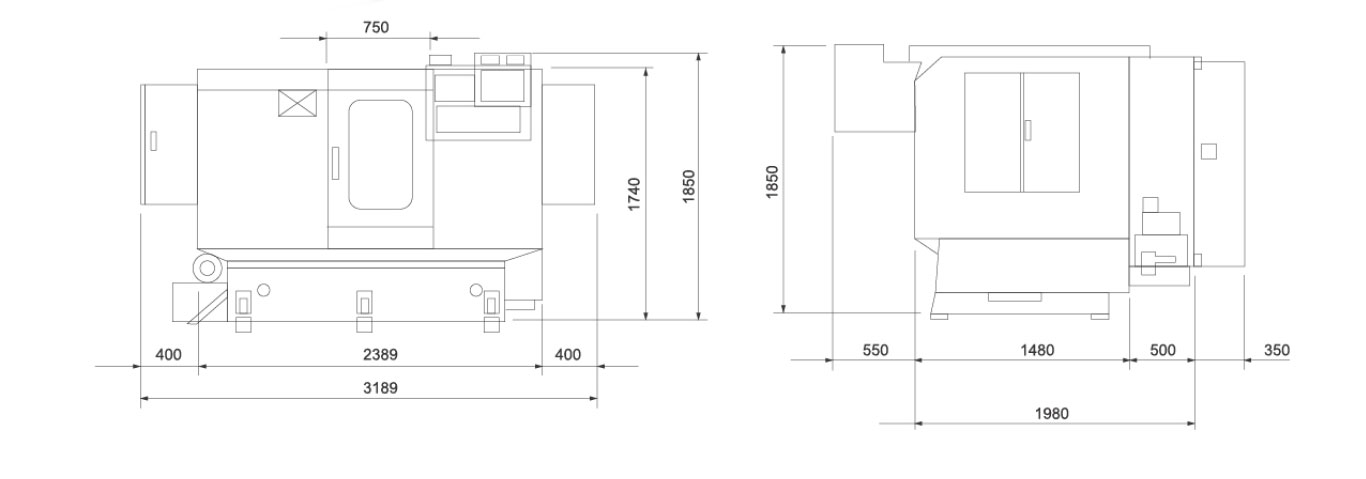

Machine Dimensions #

Drawing unit: mm

For further details or to discuss your application requirements, please contact us.