Embracing Circular Economy in Precision Machinery #

KO-YAN Precision Machinery (COMORK), situated in the heart of Taiwan’s precision machinery cluster, distinguishes itself through a commitment to sustainable manufacturing and circular economy principles. Leveraging over two decades of expertise in precision machining, the company places a strong emphasis on user experience in equipment research and development, offering tangible benefits to the industry.

Integrating Circular Economy Concepts #

At the start of 2024, consultants from the Plastics Industry Technology Development Center visited KO-YAN’s facility to promote and assess the implementation of circular economy concepts. This collaboration provided valuable insights into optimizing every stage of the equipment lifecycle—from design and manufacturing to usage and recycling—positioning KO-YAN as a key driver in helping customers adopt circular economy practices.

Industrial Cycle Thinking in Action #

KO-YAN Machinery applies its robust metal processing and R&D capabilities to serve clients with an ‘industrial cycle’ mindset. This approach is reflected in several core areas:

-

Product Design: By modularizing mechanical components, KO-YAN ensures that equipment is easy to disassemble, repair, upgrade, remanufacture, and recycle. This design philosophy extends the durability of machinery, conserves energy, and reduces resource consumption.

-

Process Optimization: The innovative GO-350CNC internal and external diameter compound grinder combines the functions of internal and external diameter grinding. This integration not only meets stringent accuracy and yield requirements but also enables users to perform multi-surface grinding in a single clamping operation. The result is enhanced production efficiency, better space utilization, and maximized resource efficiency.

- Refurbishment and Remanufacturing: Through comprehensive inspection and replacement of parts, KO-YAN restores equipment to a nearly new condition. This practice extends the service life of machinery and reduces the generation of scrap metal, such as casings, thereby contributing to carbon reduction.

International Presence and Recognition #

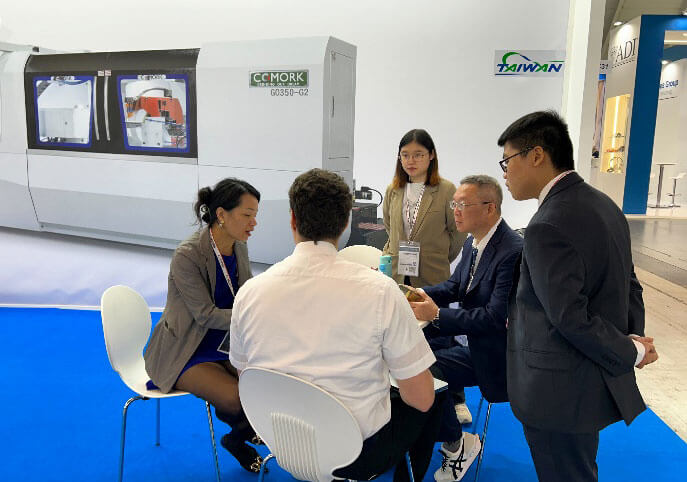

KO-YAN Precision Machinery actively participates in international exhibitions to showcase its OEM/ODM grinding machines and solutions. Following the pandemic, the company arranged for multiple international events, including its inaugural appearance at GrindingHub 2024 in Stuttgart, Germany, organized by the German Machine Tool Manufacturers Association (VDW).

The event was a notable success, attracting numerous buyers and generating positive feedback from European markets. General Manager Zhou Quanji highlighted the strong potential of the COMORK brand in Europe, with active inquiries from Germany, Turkey, and other Eurasian regions.

By integrating circular economy concepts into its operations and maintaining an international outlook, KO-YAN Precision Machinery (COMORK) continues to support customers in achieving low-carbon manufacturing and sustainable industrial practices.

COMORK's GO-350CNC Internal and External Diameter Compound Grinder

COMORK's GO-350CNC Internal and External Diameter Compound Grinder