Insights from the Perspective of Both Manufacturer and End-User #

At COMORK, our unique position as both a manufacturer and an end-user grants us a deep understanding of what users truly require from grinding equipment. Drawing on over 20 years of accumulated grinding technology and experience, we are committed to developing solutions that are sensible, valuable, and convenient for our customers.

Technical Advantages #

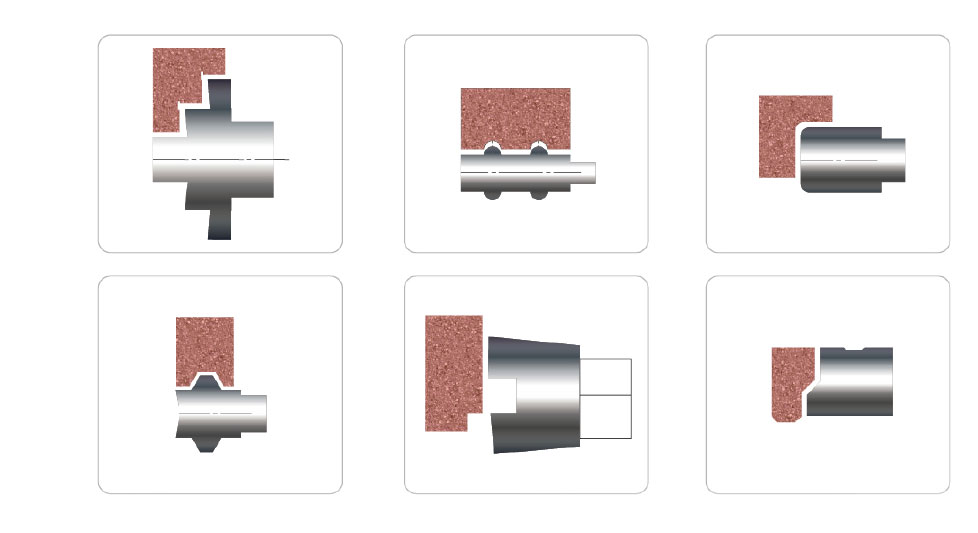

1. Curved Surface Grinding #

We leverage our independently developed know-how in pictoprogramming and processing to advance the technology in the grinding field. This expertise enables us to deliver superior curved surface grinding capabilities, enhancing both precision and versatility.

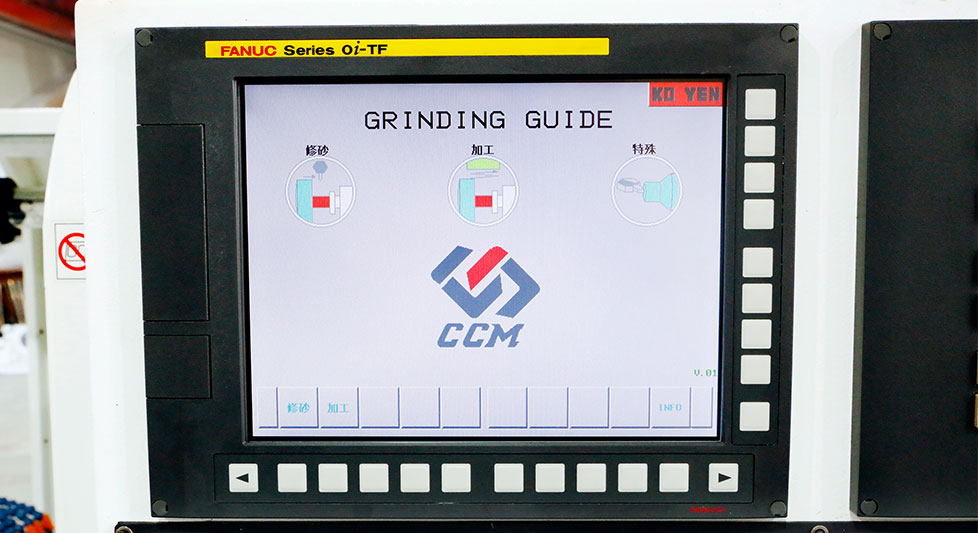

2. Pictogramming for User-Friendly Operation #

Our original pictogramming, based on the FANUC system, ensures that all controls are clearly and ergonomically arranged. The manual control unit plays a crucial role, allowing setup close to the grinding process. Built-in security settings and error warnings help prevent input mistakes, enabling even new operators to complete setup procedures and begin manufacturing with confidence.

3. Multifaceted Processing #

Through specialized controller software and design, our machines are capable of grinding complex workpieces and performing multifaceted processing in a single operation. This approach ensures high efficiency and precision, while also reducing manufacturing costs.

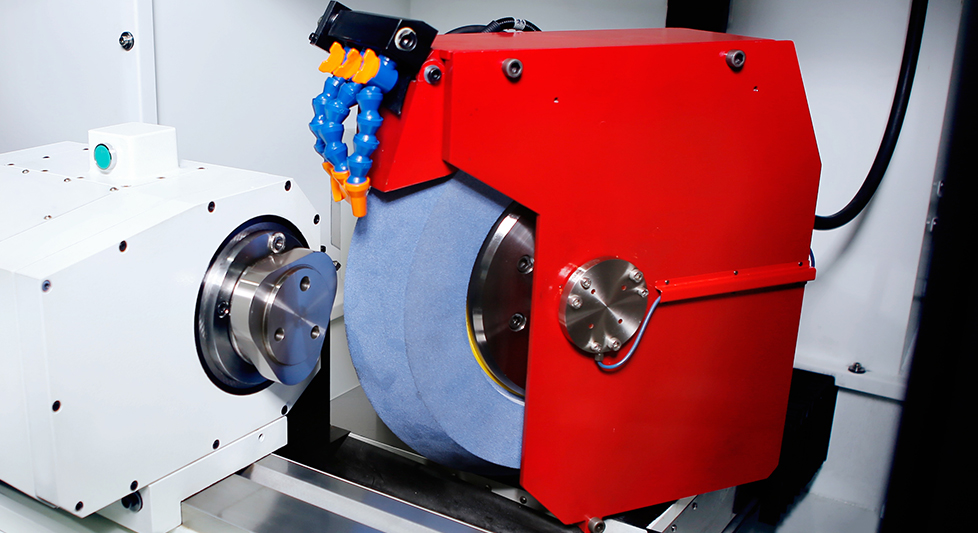

4. Acoustics Monitoring System #

Our acoustics monitoring system reduces wheel dressing cycle time and improves both efficiency and stability. By preventing wheel crashes and extending the service life of spindles and wheels, this system also monitors grinding quality to ensure machining accuracy.

Our ongoing commitment is to continue developing advanced grinding equipment that meets the evolving needs of users, combining practical experience with innovative technology.