Precision and Capability in In-House Machining and Inspection #

COMORK builds on over two decades of CCM’s grinding technology and experience, emphasizing both quality and efficiency in every aspect of production. Unlike many small and medium-sized factories that focus solely on assembly, COMORK takes a comprehensive approach: approximately 80% of the company’s machine and spindle parts and accessories are manufactured in-house. This strategy ensures tight control over both accuracy and delivery schedules.

Machining Equipment #

To support its manufacturing capabilities, COMORK operates a range of advanced machining equipment, enabling the production of high-precision components and assemblies. The following machines form the backbone of the company’s production line:

| Equipment Name | Quantity |

|---|---|

| COMORK GO-356 CNC Cylindrical Grinding Machine | 2 |

| COMORK GO-354 CNC Cylindrical Grinding Machine | 2 |

| COMORK GO-350 CNC Hybrid ID&OD Grinding Machine | 2 |

| COMORK GJ-400A CNC Hybrid ID&OD Grinding Machine | 6 |

| DMG CTX Beta 800 Universal Turning Center | 2 |

| Horizontal Turning Center | 7 |

| Vertical Machining Centres | 3 |

| Rotary Table Surface Grinding Machine Ram Type | 3 |

Inspection Instruments #

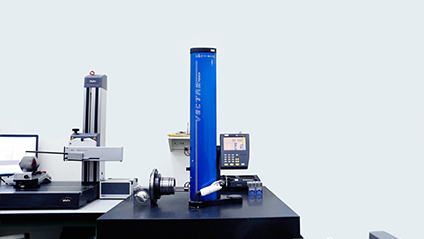

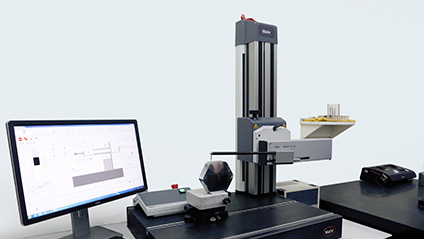

To guarantee consistent quality and meet customer expectations, COMORK employs a range of precise inspection instruments. Objective test data and advanced measuring equipment are central to the company’s quality assurance process. Production technicians are equipped with various dial gauges, bore gauges, and micrometers to ensure accuracy at every stage.

| Equipment Name | Quantity |

|---|---|

| ZEISS Three-dimensional Coordinate Measuring Machine | 1 |

| Vectra-touch1 Height Gauge | 1 |

| MAHR Profilometer | 1 |

Through this combination of in-house manufacturing and rigorous inspection, COMORK delivers reliable, high-precision products tailored to the needs of its customers.